MARMOREAL® IS AN ENGINEERED MARBLE FOR ARCHITECTURAL SURFACES DEVELOPED IN COLLABORATION WITH THE BRITISH DESIGNER MAX LAMB.

Marmoreal® is offered in two colourways, one with a white background, and the other black. Each version is composed of four classical Italian marbles and is a material exploration that celebrates the individual qualities of these stones while acknowledging that their combination leads to something even more compelling. Suitable for interior architectural surfaces, this large-aggregate, pre-cast marble terrazzo offers an original material language with strong visual values. It skilfully balances a fifteenth-century craft tradition with modern engineered-stone technologies. The word ‘marmoreal’ means ‘marble-like’; this Marmoreal® is composed of approximately 95 percent marble and 5 percent polyester resin binders.

FORMATS + FINISHES

Marmoreal® is available in a range of standard dimensions and finishes that suit the randomness of the material yet give the impression of a continuous surface. The smaller 300 ✕ 300mm tiles provide the flexibility to install in small spaces in a consistent grid. The generous 600 ✕ 600mm tiles and 3050 ✕ 1240mm slabs allow greater opportunities for customisation. Blocks measuring 3050 ✕ 1240 ✕ 850mm are available on special request. We offer a honed finish, which gives a perfectly matte, natural expression of the marbles, or a polished finish, which gives a more saturated, reflective surface.

Marmoreal White tiles in two sizes, 600 ✕ 600mm and 300 ✕ 300mm.

Marmoreal White Slab, 3000 ✕ 1200mm.

Marmoreal Black Slab, 3000 ✕ 1200mm.

| TYPE | SIZE | THICKNESS | FINISH |

|---|---|---|---|

| TILE | 300 ✕ 300mm | 20mm / 30mm | Honed/Polished |

| TILE | 600 ✕ 600mm | 20mm / 30mm | Honed/Polished |

| SLAB | 3050 ✕ 1240mm | 20mm / 30mm | Honed/Polished |

CERTIFICATIONS

HOW TO BUY

Marmoreal® tiles and slabs are made to order. Production lead time is typically 4 weeks. Clients in the Greater London area can often have a reduced lead time. Please contact us directly for details and availability.

We ship worldwide direct from our factory in Italy. Transport times depend on destination and method of shipping selected. Sea, road and air freight options are available. Once you have specified material quantity and final destination, we will source multiple quotes and pass along the option that best suits your needs and budget.

HOW TO MEASURE

SLAB: Marmoreal® slabs measure 3050 ✕ 1240mm with a finished usable area of ±3000 ✕ ±1200mm and thicknesses of either 20mm or 30mm. We advise use of 30mm slab for work surfaces and 20mm for walls, cladding and floors. We do not sell partial slabs or fabricate custom slab sizes on a per project basis. This work would be carried out by a local tradesperson, likely a stone fabricator. We advise working with such a fabricator or architect to ensure calculations on material are correct for your project and to account for any overages necessitated by the design or installation of your project.

TILES: Tiles are available in 20mm and 30mm thicknesses and custom sized tiles are also available upon request. We advise a 10% contingency on top of the minimum quantity needed to account for any errors that arise during installation such as accidental breakage and to preempt any unforeseen circumstances that may present themselves.

CUSTOM ORDERS

Please contact us for enquiries about bespoke projects and items including alternative thicknesses for slabs and tiles and custom furniture.

CASE STUDIES

OFFICES, BERLIN

Marmoreal black and white tiles were chosen for the renovation of the historical Palais Eger in Berlin by David Kohn Architects and Nord Studio Berlin now hosting the new offices of Euroboden. Photos by Will Pryce.

RENOVATED 1970s FAMILY HOME IN EAST HAMPTON

This renovation of a 1970s family home in East Hampton by Wythe Studio Architect uses Marmoreal white for the kitchen and table top. Slab 3m thick, honed. Photos by Devon Banks Photography.

STORY

We were curious to see what kind of stone Max would create, how his rational approach to furniture design would translate in material design and if he would work differently with a stone he creates opposed to one he takes from the earth.

Marmoreal by max lamb. Installation for Salone Del Mobile 2014.

Lamb’s ongoing Quarry series was the starting point for our collaboration with him. These sculptural works are characterized by their raw appearance, generous scale and honestly celebrate the qualities of a given stone’s natural shape, texture, and even its historical context.

We researched different man-made stone technologies and assessed which processes provided the most opportunity to achieve a desired result. A thorough survey of the existing products, past and present, was conducted to ensure originality.

DeLank Cornish Granite used by Lamb in the design of a chair and side table.

Approach to working with stone as it appears in Max Lamb's China Granite Project.

Investigating the thousands of pre-cast terrazzo and agglomerated stone recipes in existence.

Agglomerated stone recipe archive.

Archive image of an early precast terrazzo production from 1965.

Archive image of an early precast terrazzo production from 1965.

Terrazzo’s sustainable roots date back to fifteenth-century Venice, where craftspeople used waste materials — for instance local stone off-cuts and chips from the construction of palazzos — to make decorative mosaic-like flooring solutions. Eventually they began introducing glass, metals, and even concrete, all while consistently using local-material waste. Marmoreal® acknowledges this history by using waste stone from Italian quarries, most of it locally sourced.

Quarry where Biancone marble is sourced.

Archive image of early twentieth-century terrazzo making.

Rosso Sant'Ambrogio dimension quarry where we source the Rosso Verona aggregates.

PROCESS

After settling on making a precast terrazzo, extensive compositional studies followed and Lamb arrived at the idea of using large marble rocks as the bulk of the recipe to emphasize the inherent stoniness of human-made stone. This approach is in contrast to the typically small, speckled pieces of aggregate typical of terrazzo.

Conceiving the Marmoreal composition.

Marmoreal composition work.

An early Marmoreal concept sketch by Max Lamb.

Italian marbles turned into Marmoreal. Giallo Mori, Verde Alpi and Rosso Verona.

Rosso Verona, Giallo Mori, and Verde Alpi are the three Italian marbles featured in Marmoreal. Bianco Verona is used to create the white-background version, and Grigio Carnico is used for the black-background version. All of these marbles are natural materials and thus vary from batch to batch. The variations are part of the inherent beauty of natural stone and ensure that each piece of Marmoreal® is entirely unique.

Rosso Verona, a red nodular limestone of the Jurassic period from northern Italy, is the prevailing stone in much of Veronese classical architecture. The entire city of Verona feels as if it is made from it. Its visual quality is the most predictable of the three featured stones, with colours ranging from earthy reds like dry clay to more saturated brownish reds characterised by fine circular patterns and stylolitic veins.

Giallo Mori is a bright, ochre-yellow marble from Trentino-Alto Adige, with both light and dark veins and the occasional small white quartz patches. The colour can range from pale yellow to dark Dijon mustard. The texture is often flat but can sometimes contain small white speckles that resemble a mass of microbes.

Rosso Verona Aggregates.

GIallo Mori aggregates.

Verdi Alpi aggregates.

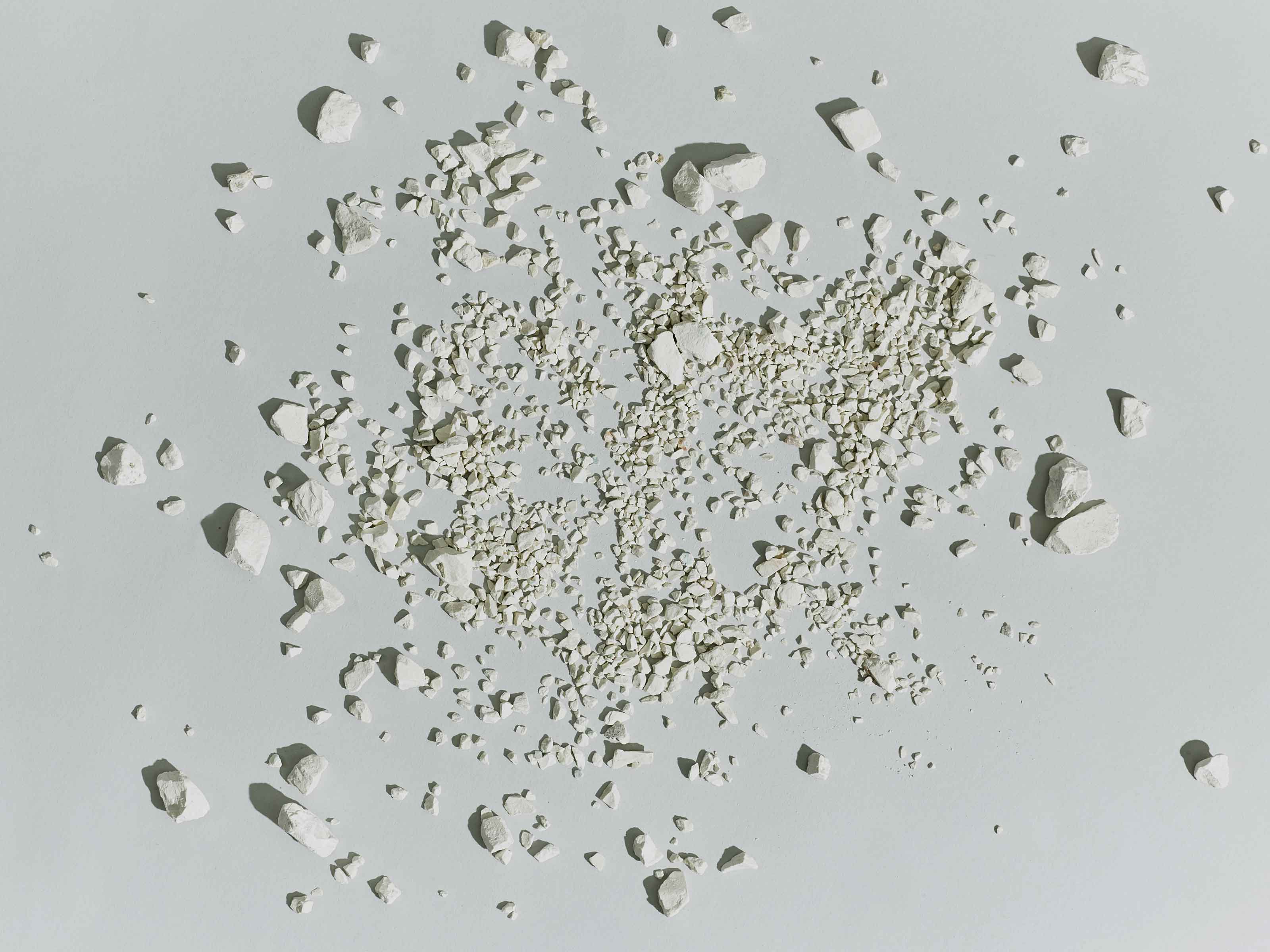

The various particle sizes of Biancone marble used in the background of the white variant.

Weighing the ingredients that go into a block production.

Verde Alpi is a traditional marble from Valle d’Aosta, known for its intense green colour and contrasting white quartz veins. The most varied of the three marbles, its particles can have a high quartz content, making the stone a glassy white or emerald green, or an absence of quartz, making it nearly black.

Bianco Verona makes up the background matrix for Marmoreal White. This traditional Veronese marble is characterised by its opacity and textural flatness, perfect attributes to serve as a canvas for the three primary marbles. Bianco Verona can vary in colour from off-white to cream, pink, or grey. In the Marmoreal® development phase, it became clear that this stone provided better contrast than its more famous counterparts, Carrara and Botticino.

Grigio Carnico is the background for Marmoreal Black. This dark grey to black limestone from Alpi Carniche contains some pronounced white and grey veining, but on the smaller scale used to create a matrix, these qualities are homogenised and give the appearance of a galactic scenescape.

Mixing marble powder, resin and the larger stones to make a marble slurry that is then cast and cut into Marmoreal.

Cast blocks cure in the yard for two weeks before cutting them into slabs.

Marmoreal being cast into blocks.

Machinery used to cut slabs.

Tile cutting process.

ESSAY

Marmoreal:

Rebellious Child of the Terrazzo Family

by Vicky Richardson

The Royal Institute of British Architects in central London turns out to be a good place to start researching this article on Marmoreal. Its library has no books that can help me, but the Art Deco entrance hall features a spectacular terrazzo floor, and the material wraps around the interiors of WCs and corridors. Marmoreal is a variety of terrazzo with its own unique design and manufacturing process. Developed and produced by Dzek in collaboration with the British designer Max Lamb in 2014, Marmoreal is a product of our times in both the aesthetic and the technological sense—although it could not exist without the tradition of terrazzo, which dates back to the fifteenth century.

The RIBA headquarters was completed in 1934 to a design by the British architect George Grey Wornum. Strongly influenced by Scandinavian Functional- ism, particularly Gunnar Asplund’s Stockholm City Library, its use of terrazzo is a great example of the revival of the material as a fashionable, decorative finish in the 1930s. The interiors were designed in collaboration with artists and craftspeople and feature materials and motifs from around the world, reflecting RIBA’s desire to represent the profession internationally. Although the building was highly experimental in its use of materials, it was constructed during an economic downturn and the budget was tight. Terrazzo would have been understood as a fashionable but hard-wearing and cost-effective choice of finish.

It’s thought that terrazzo was first developed as a flooring material in Italy in the fifteenth century, when mosaic craftspeople working with marble realised that the disused chips of material, when trodden into the ground, became a resilient surface. Palladio used a variety of terrazzo in villas in the Veneto region of northeastern Italy, which perhaps led to the naming of a variety of terrazzo with larger chunks of marble as Palladiano.

In the twentieth century terrazzo was revived at moments when architectural style embraced decoration. It was used widely in public buildings such as hospitals and civic centres, as it is durable and easy to clean but still carries an air of grandeur and an association with European style. The Italianate Ironmonger Row swimming baths in London’s Clerkenwell (1931), where terrazzo was used for floors and partitions, is a good example. The building was beautifully restored by Tim Ronalds Architects in 2012, and both precast and in-situ terrazzo were used for floors and walls in the reception and main staircase.

Terrazzo became fashionable again in the 1950s at the start of the post-war boom, and yet again in the 1980s in part as a reaction against the utilitarianism of Modernism. In 1982 the Japanese designer Shiro Kuramata came up with the idea of using shards of coloured glass instead of stone in a type of terrazzo he named Star Piece. He went on to use the highly polished, glittery material for an entire interior at Design Gallery 1953 in Tokyo and for the Issey Miyake store in Ginza. The effect was a speckled pattern that appeared to flatten three-dimensional objects and spaces. Kuramata described it as ‘the debris of meaning’. In 1983 the designer joined forces with the Italian design collective Memphis to produce a series of tables (Nara, Tokyo, and Kyoto) using Star Piece terrazzo; and later he translated the material into a graphic pattern that was applied to fabric and other surfaces, including packaging for the perfume L’Eau d’Issey in 1990.

As a means of extending its ideas into print, in 1988, Memphis founder Ettore Sottsass and his wife, the design critic Barbara Radice, founded a biannual magazine named after one of their favourite materials: Terrazzo. Radice wrote in her first editorial that the word, with its dual meaning—‘terrace’ or ‘place of encounter’ in Italian, and ‘mosaic flooring’ in English—expressed the ‘idea of hardness of stone, of building and also the idea of leisure suggested in English by the multi-coloured pleasantness of the material’. ‘Names’, she continued, ‘always carry with them a magic aura, a mysterious power. I like to think that Terrazzo can call forth the sum of both meanings in the two languages and be enhanced by the qualities.’

The meaning of the word ‘marmoreal’ is ‘marble-like’, and in Italian it refers to things that look like marble but are not actually made from it. Although it is born of a very different impetus and era, Marmoreal captures something of the joyful spirit of Memphis. It celebrates the natural quality of marble and relishes its multi-coloured variations. Four types and colours of marble are used in Marmoreal: green Verde Alpi, ochre-yellow Giallo Mori, and red Rosso Verona are set into either a white Bianco Verona or a black Grigio Carnico. But the material is not just a version of terrazzo. It brings a contemporary array of associations, and uses new techniques in its manufacturing. Conceived and designed by Max Lamb, a designer who has dedicated himself to exploring materials in a practical and artistic sense since graduating from the Royal College of Art in 2006, Marmoreal celebrates the ‘stoniness of stone’.

Lamb first worked with stone in 2007, when he carved a chair from limestone quarried in the north of England (the Ladycross Sandstone Chair). He has since explored the geological and material properties of different stones while on res- idencies in many parts of the world, including China, Russia, and Ireland. Lamb conceived Marmoreal as a variety of terrazzo that uses large chunks of historically important Italian marble, showing his appreciation for the colours and natural patterning. The aggregates in Marmoreal are not only unusually large, but also carefully composed according to a ‘recipe’. As Lamb explains, ‘It is the aggregate size in relation to the background matrix that gives Marmoreal its graphic quality and its performance as an engineered material.’

Alongside developing Marmoreal as a material for architects and designers to play with, Lamb has used it for his own series of architectonic furniture and sanitaryware. To be consistent with the sustainable philosophy of Marmoreal, the furniture uses only standard-dimension slabs and tiles in order to reduce waste. These pieces look particularly striking within a setting of Marmoreal walls and floors and take the ‘all-over’ aesthetic to an extreme, an approach that Dzek founder Brent Dzekciorius describes as a minimal maximalist Gesamtkunstwerk. The furniture pieces also demonstrate the essential quality of Marmoreal as an engineered, mass-produced material that can be used to create unique one-offs, each with a slightly different ‘slice’ of stone.

Lamb’s furniture and the growing catalogue of interiors where Marmoreal has been used as a surface material (private residences, retail environments, public spaces) demonstrate its versatility and style. Historic twentieth-century examples of terrazzo continue to be lovingly cared for by their owners, not simply because they are hard-wearing and practical but because they contribute something unique to the character of the architecture. Its sustainable engineering and simple, cost- effective format make Marmoreal a pragmatic choice. But aesthetically, its expressive chunks of coloured marble render Marmoreal the rebellious, artistic child of the terrazzo family.

-2017